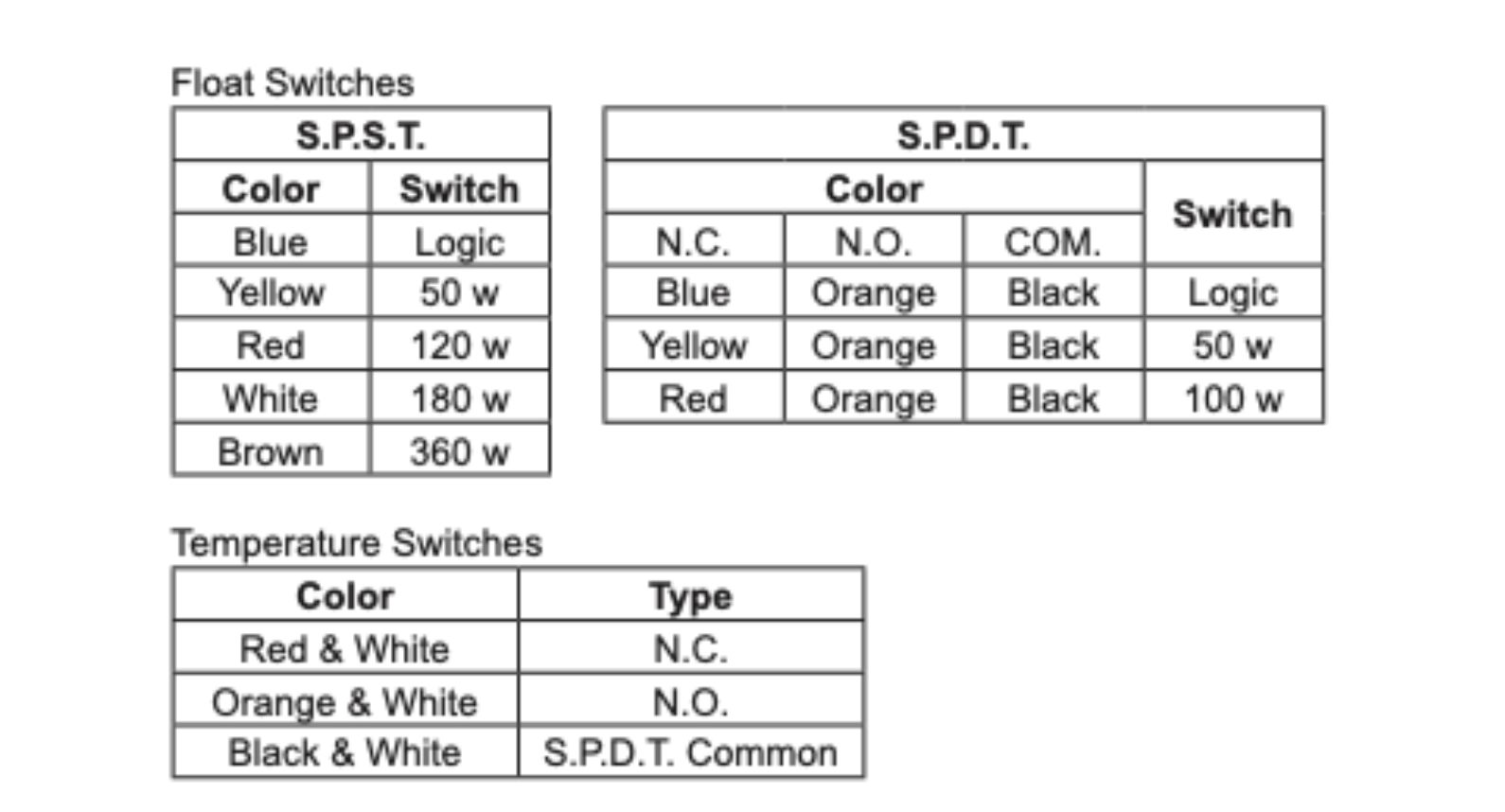

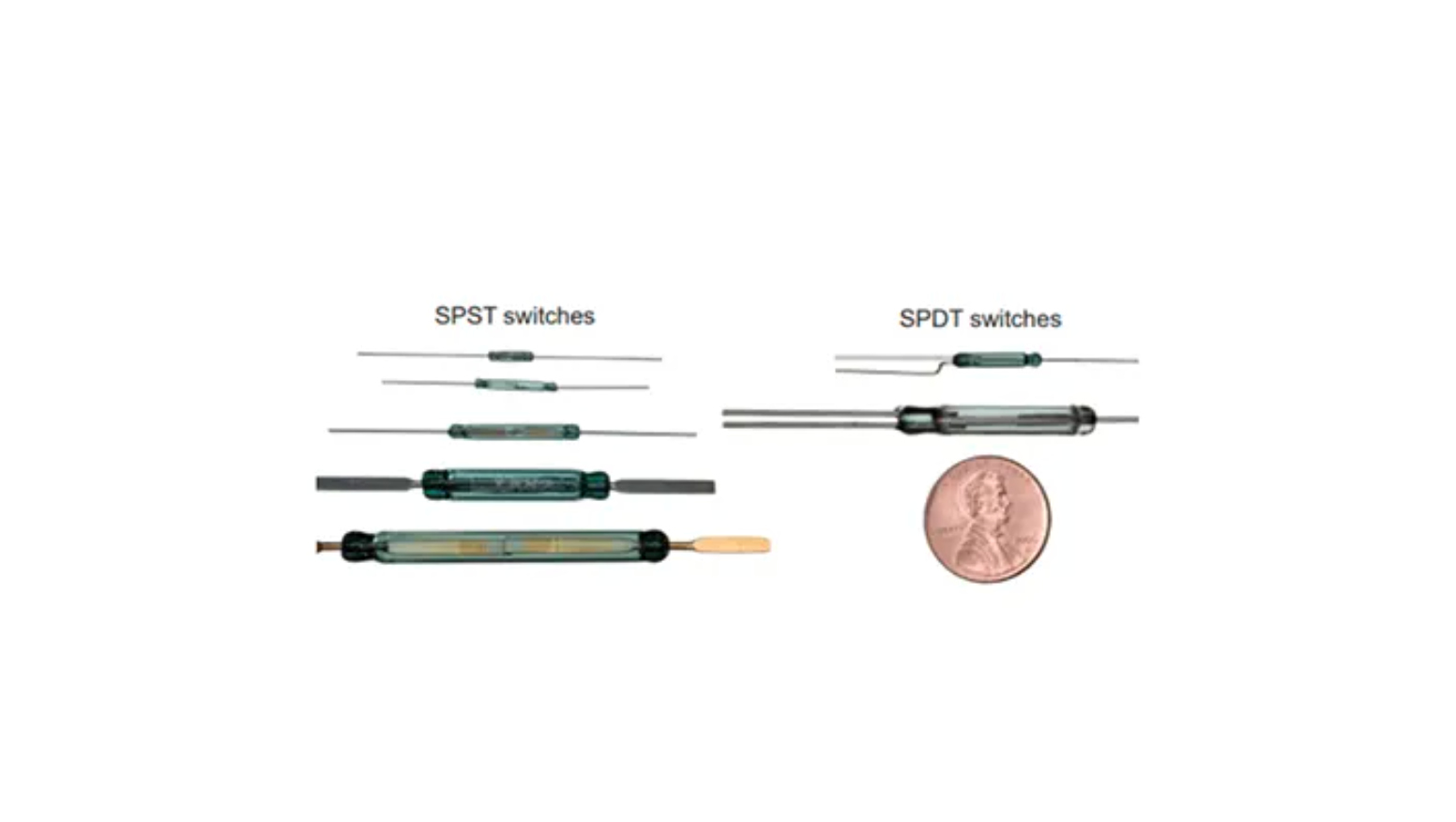

Advanced Control Technology uses the highest quality switches in our sensors. The most common switches are listed here. There are many 100’s of switch types and each individual switch has many sensitivity options. We will evaluate your application and match a switch with your application based on our years of experience. We strongly recommend testing in real world conditions for final approval.

ENGINEERING DATA

Liquid Level Reed Switch Data

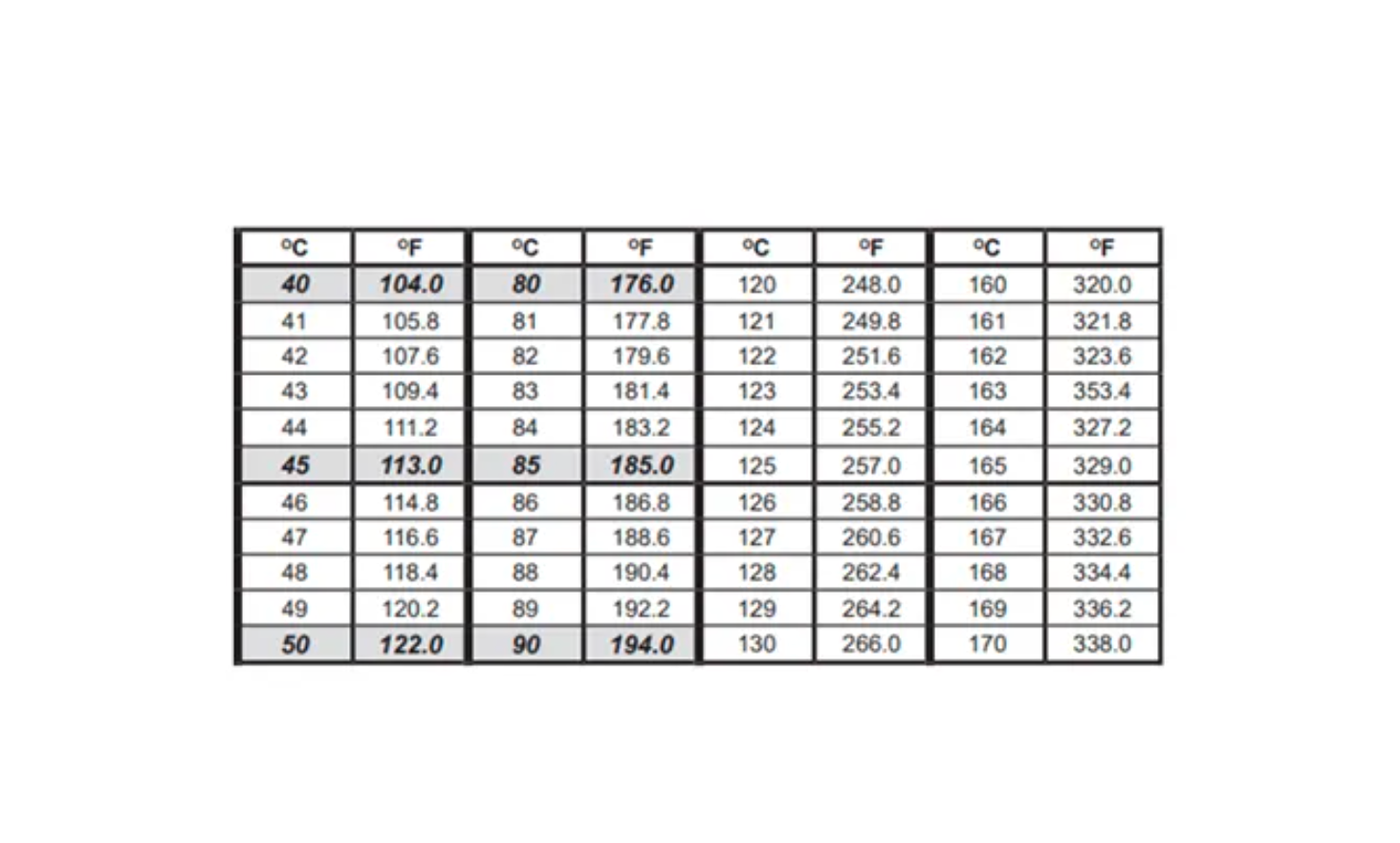

Temp. Switches, Thermistors, and Thermocouple Data

Advanced Control Technology uses the highest quality temperature sensing devices in our sensors. The most common and stocked for quick shipping are listed here. There are many 100’s of temperature sensors available and we will evaluate your application with you and match a temperature sensor that best matches your application requirements based on our years of experience.

Level Switch Failure Data

Warning

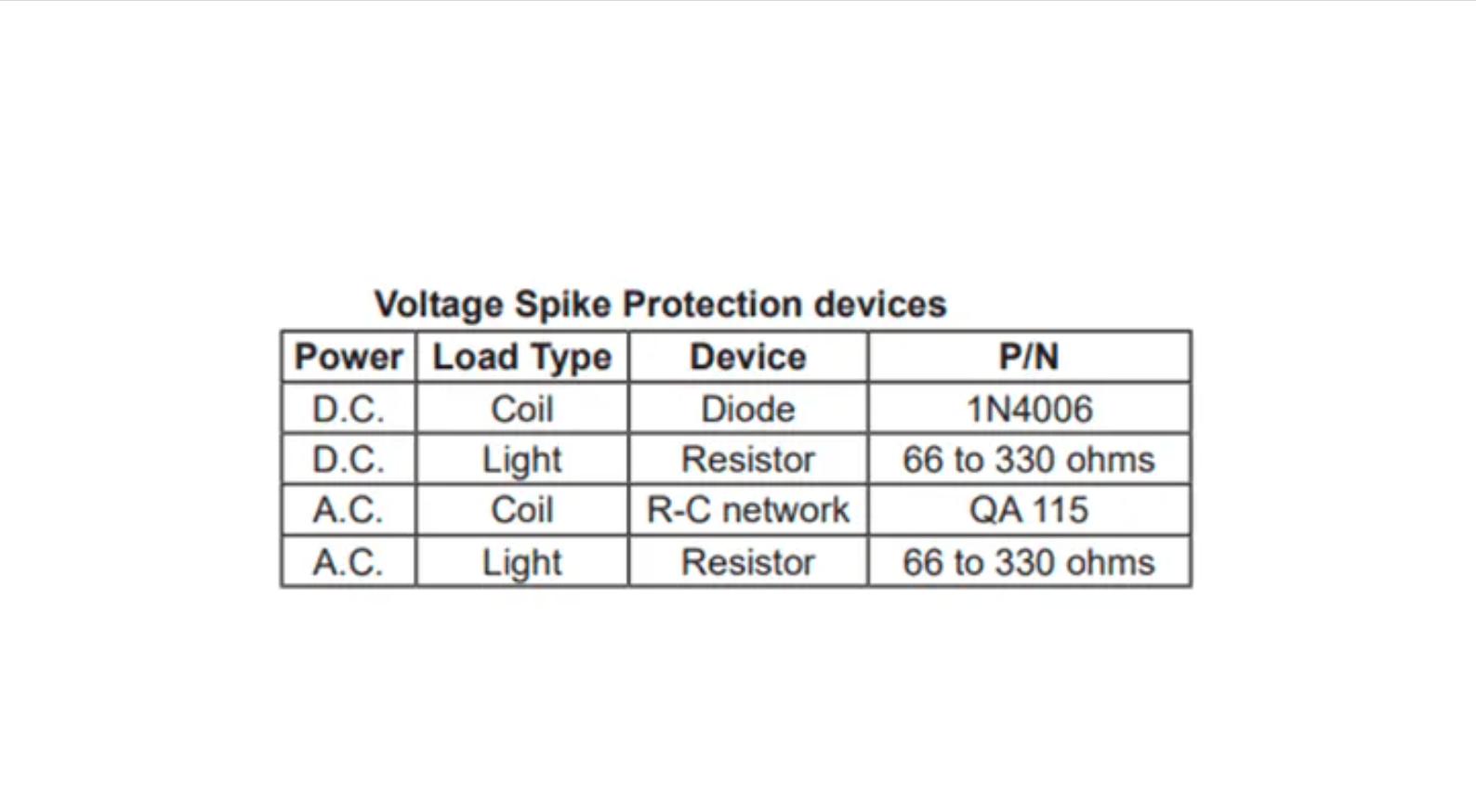

Switch failure will occur without protection. It is your responsibility to incorporate this protection. Surge protection devices should be mounted within 10” of the load or switch.

Inductive loads

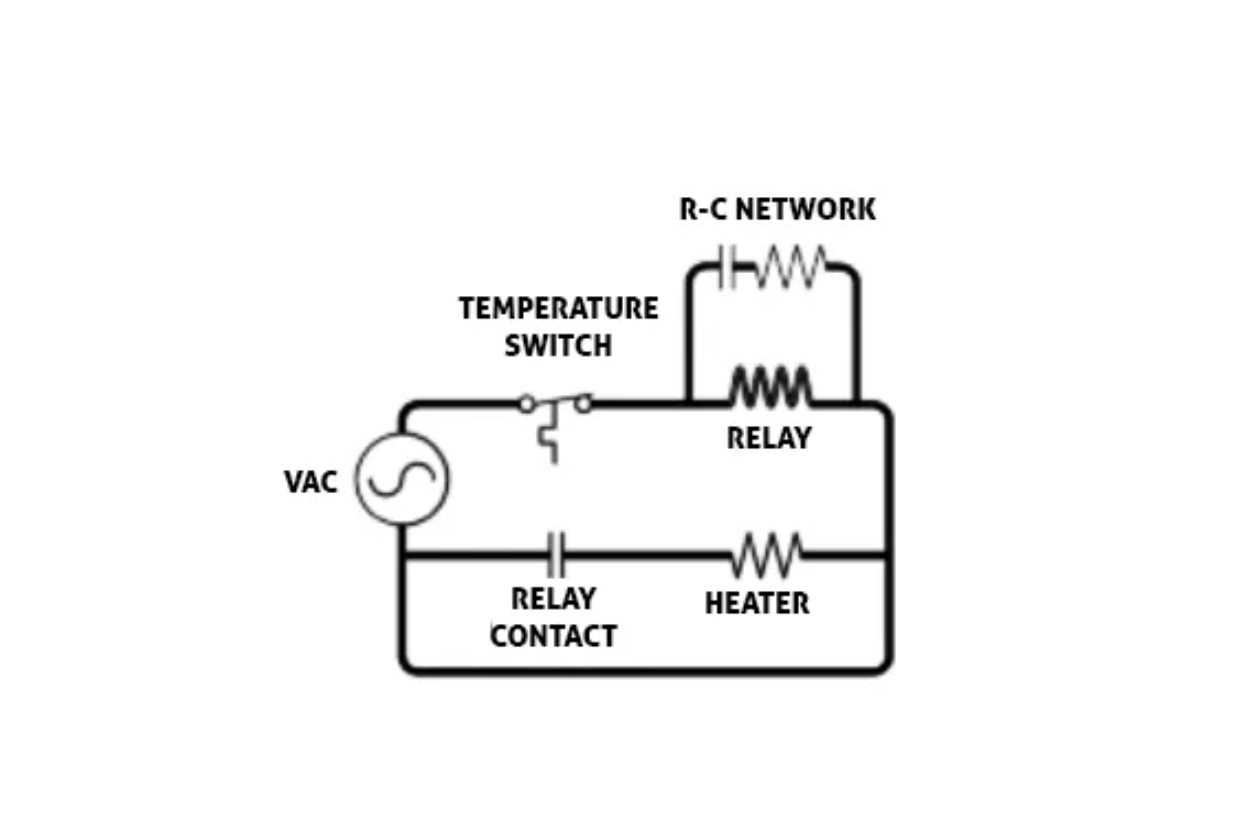

Inductive loads produce very large voltage spikes which will cause reed switch failure. Typically inductors such as relays, solenoids, and motors will cause voltage spikes of several hundred volts which will severely damage contacts and greatly shorten life. This spike happens when the contact opens causing the electrical field to collapse, generating what is known as counter emf. Counter emf must be reduced to safe levels in order to achieve rated life and load specifications.

Incandescent lamp loads

Inrush current for incandescent lamps is 10 to 15 times the rated current as specified by the manufacturer. High current draw happens when the lamp is turned on. The lamp has low resistance that increases with time ( approximately 1 second ).

Temperature Switch Failure

The switch is not operating at the correct set point temperature. Self heating errors or higher than recommended current through the switch will be the cause of the problem. Self-Heating is commonly found when a switch is electrically connected to the heating element directly. The switch contacts heat up with the increase in current through the switch. The switch combines the ambient temperature and the internal switch temperatures together. Temperature switches are not to control a fan or heater directly. Fans or heaters with sufficient current draw will permanently change the set point of the bimetallic switch. Follow this recommended electrical schematic for temperature switch wiring.

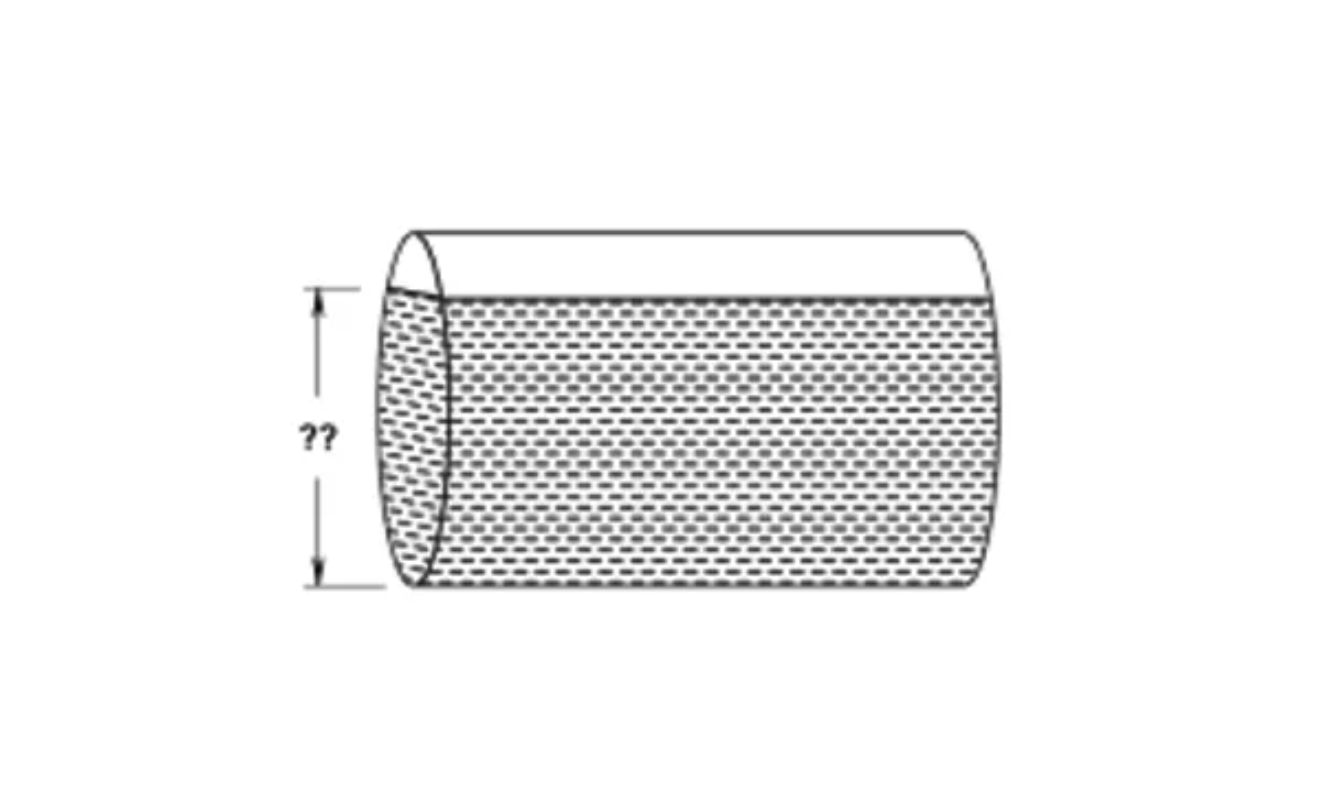

Volume of liquid in a tank

The volume of liquid in your tank is a crucial part of designing an effective level sensor for different applications. Additional information in the catalog will help you determine the volume for these different tanks: rectangular shaped tank, round tank standing vertically, round tank laying horizontally.

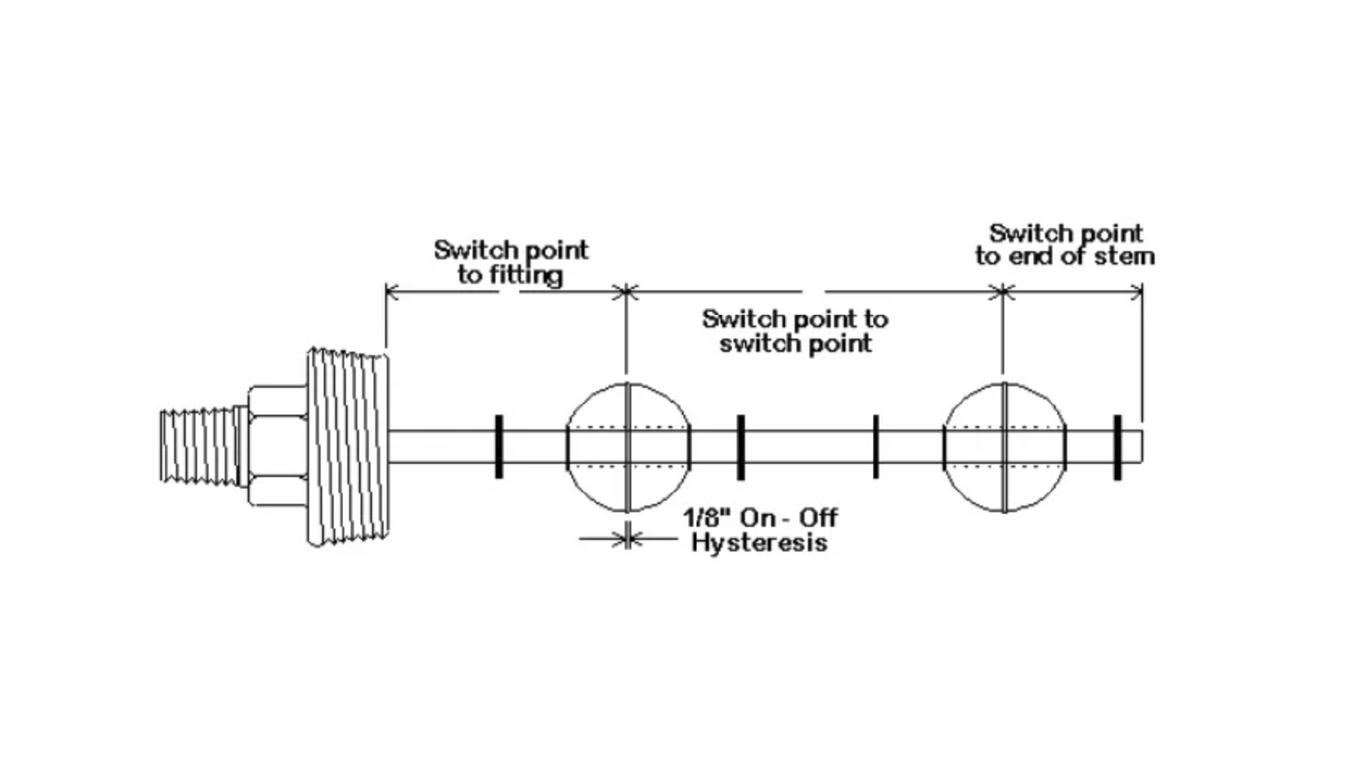

Switch Point Guide

| Float Type* | Switch Point to Fitting | Switch Point to Switch Point | Switch Point to End of Stem |

|---|---|---|---|

| A | 1-1/16" | 1-5/8" | 1-1/8" |

| B | 1" | 1-1/2" | 1" |

| C | 1" | 1-1/2" | 1" |

| D | 1-3/8" | 2-1/2" | 1-3/8" |

| E | 1-3/8" | 2-1/2" | 1-3/8" |

| F | N/A | N/A | N/A |

| G | 1-1/2" | 2-1/2" | 1-1/2" |

| H | 1-1/2" | 2-1/2" | 1-1/2" |

*Float type, above refers to Float data chart below.

Numerous component options are available which offer reductions in dimensions listed above. Call A.C.T. application engineers at 1-877-800-8820 or e-mail us for additional data to customize a sensor for your application. Switch point repeatability is 1/16" standard, closer tolerances available.

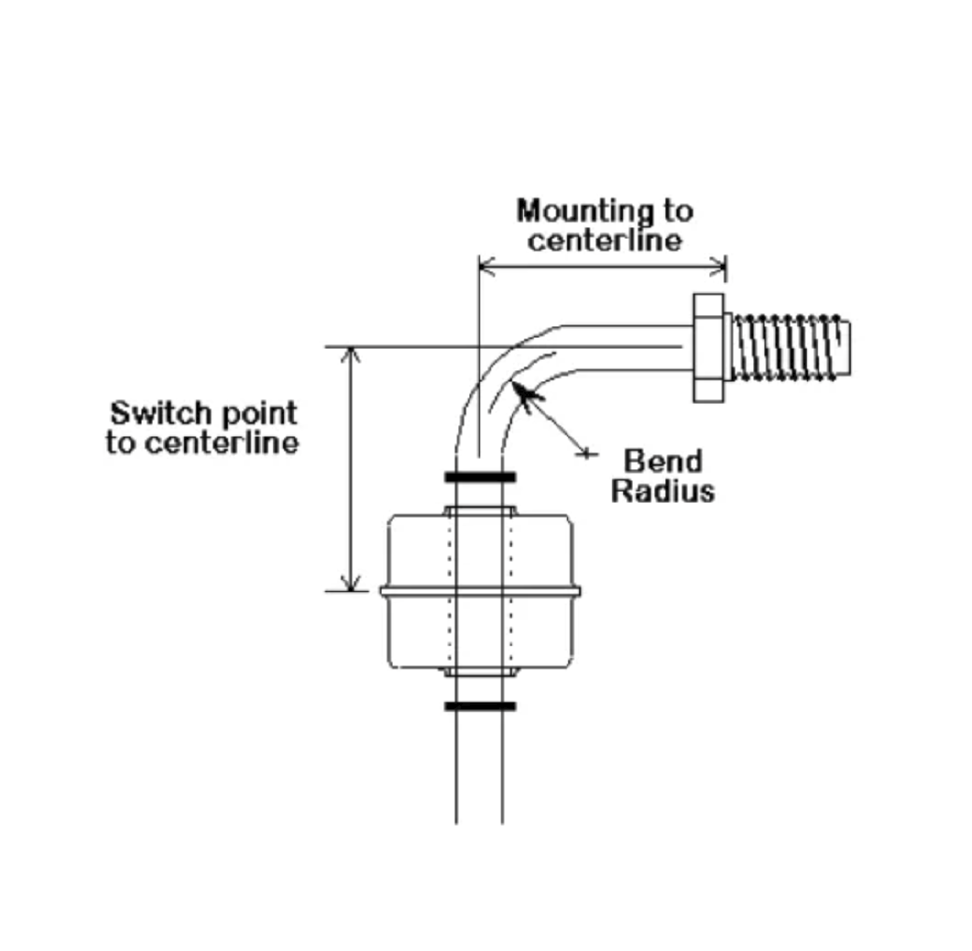

Bent Stem Distance Guide

| Float Type* | Fitting to centerline | Switch Point to Centerline | Bend Radius |

|---|---|---|---|

| A-B-C | 1-3/4" | 1-3/4" | 3/4" |

| D-E | 2" | 2-1/16" | 1" |

| G-H | 3" | 3-3/16" | 1 1/2" |

Float Data Chart

| Float Type | Type | Float Series | Material | Outside Diameter | Length | Specific Gravity | Max. PSI | Max. Temp. | Notes |

|---|---|---|---|---|---|---|---|---|---|

| A | S/S | 500 | 316 Stainless | 7/8" | 1-9/16" | .69 | 450 | 300 | Fits through 3/4" npt |

| A | Plastic | 500 | Polypropylene | 11/16" | 1-1/8" | .85 | 150 | 230 | Fits through 1/2" npt |

| A | Plastic | 500 | NBR | 11/16" | 1-1/8" | .70 | 150 | 300 | Fits through 1/2" npt |

| B | S/S | 1000 | 316 Stainless | 1-1/16" | 1-1/16" | .79 | 450 | 300 | Fits through 1" npt |

| B | Plastic | 1000 | Polypropylene | 1" | 1" | .68 | 150 | 230 | For Chemicals |

| B | Plastic | 1000 | Nylon | 1" | 1" | .68 | 150 | 290 | For Petroleum |

| B | Plastic | 1000 | NBR | 7/8" | 1" | .48 | 150 | 300 | Fits through 3/4" npt |

| C | S/S | 1000 Wide | 316 Stainless | 1-1/2" | 1" | .50 | 120 | 300 | Floats in less liquid |

| C | Plastic | 1000 Wide | Polypropylene | 1-3/16" | 1" | .52 | 150 | 230 | Hex ID |

| C | Plastic | 1000 Wide | Nylon | 1-3/16" | 1" | .52 | 150 | 290 | Hex ID |

| C | Plastic | 1000 Wide | NBR | 1-1/4" | 1" | .40 | 150 | 300 | Low specific gravity |

| D | Plastic | 2000 Narrow | Polypropylene | 1-1/8" | 1-13/16" | .74* | 150 | 230 | Fits through 1" npt |

| D | Plastic | 2000 Narrow | Nylon | 1-1/8" | 1-13/16" | .73 | 150 | 290 | Fits through 1" npt |

| D | Plastic | 2000 Narrow | NBR | 1-1/8" | 1-3/8" | .61 | 150 | 300 | Fits through 1" npt |

| E | S/S | 2000 | 316 Stainless | 1-5/8" | 1-3/8" | .60 | 120 | 300 | Universal |

| E | Plastic | 2000 | Polypropylene | 1-3/16" | 1-3/4" | .69 | 150 | 230 | Chemicals resistant |

| E | Plastic | 2000 | Nylon | 1-3/16" | 1-3/4" | .68 | 150 | 290 | Petroleum resistant |

| E | Plastic | 2000 | NBR | 1-1/4" | 1-7/8" | .31 | 150 | 300 | Low specific gravity |

| F | Plastic | 7000 Tilt | Polypropylene | 1-3/16" | 1-3/4" | .76 | 150 | 230 | Mercury tilt flot |

| G | S/S | 3000 | 316 Stainless | 2-1/32" | 2" | .59 | 900 | 300 | High buoyancy |

| G | S/S | 3000 VRO | 316 Stainless | 2-1/32" | 2" | .68 | 750 | 300 | VRO series float |

| G | S/S | 3000 HT | 316 Stainless | 2-1/32" | 2" | .65* | 1000 | 450 | High temperature float |

| G | Plastic | 3000 | Polypropylene | 2" | 1-13/16" | .62* | 150 | 230 | High buoyancy |

| G | Plastic | 3000 | Nylon | 2" | 1-13/16" | .50 | 150 | 290 | High buoyancy |

| H | S/S | 3000 Cylinder | 316 Stainless | 2-1/32" | 2-1/16" | .50 | 200 | 200 | High buoyancy |

| H | Plastic | 3000 Large ID | Polypropylene | 2" | 1-13/16" | .74 | 150 | 230 | Large debris clearance |

| H | Plastic | 3000 Large ID | PVC | 2" | 3" | .66 | 50 | 100 | Large debris clearance |

| H | Plastic | 3000 Large ID | NBR | 2" | 2" | .45* | 150 | 300 | Large debris clearance |

| 6200 | Plastic | 6200 | Nylon | 11/16" | 1" | .44 | 150 | 290 | Fits through 1/2" npt |

| 6200 | Plastic | 6200 | Polypropylene | 11/16" | 1" | .40 | 150 | 230 | Fits through 1/2" npt |

| 6200 | Plastic | 6200 | Polypropylene | 11/16" | 2" | .27 | 150 | 230 | High buoyancy |

| 6300 | Plastic | 6300 | Nylon | 1/2" | 1-1/16" | *.20 | 1-3/8" | 180 | Fits through 3/8" npt |

| 6300 | Plastic | 6300 | Polypropylene | 1/2" | 1-1/16" | *.20 | 1-3/8" | 180 | Fits through 3/8" npt |

Floats are available Hollow or Solid closed cell structure.

Search

Use this section to help customers find the products they're looking for.