As the industry leader in providing liquid level sensors and controls, you are guaranteed getting the best solution for your application. Our team is compromised of engineers with 10+ years of experience and we solve every application internally without the use of sub-contractors or imported sub-assemblies.

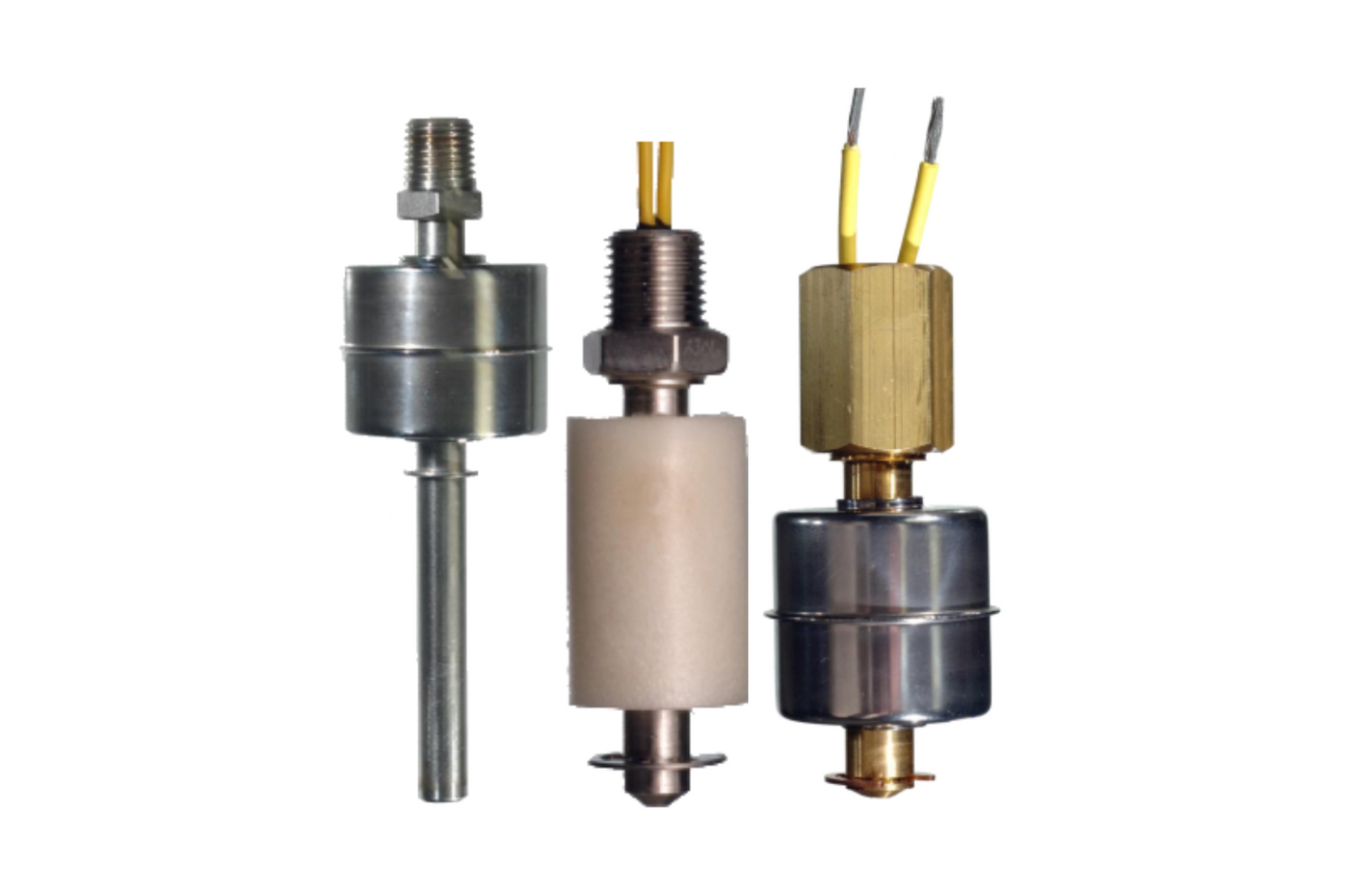

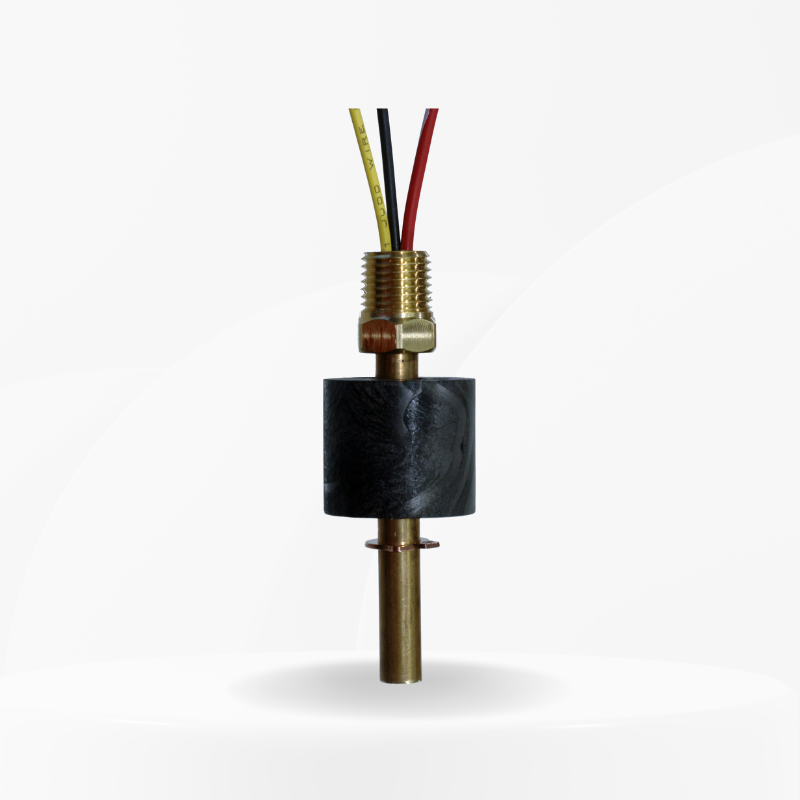

Custom Parts

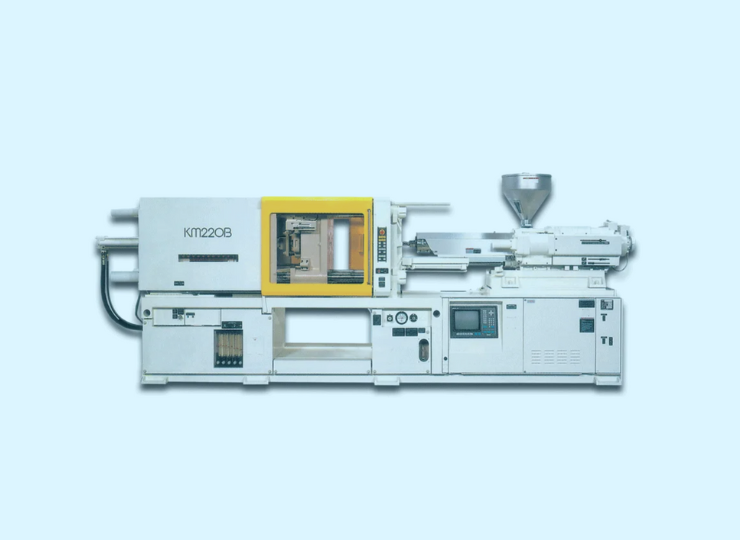

ACT will assemble our standard off the shelf liquid level and temperature sensor and various other sensor components to provide the best solution for your application. Hundreds of combinations are available with our standard components. Our in house CNC machining capabilities and plastic injection molding machines present you with unlimited options.